Filtration Systems

Cleaner Fluids. Safer Wells. Smarter Operations.

At Safety Angola, we help operators achieve peak fluid performance downhole, ensuring safe, efficient, and reliable operations from surface to reservoir. Unwanted suspended solids and fluid contamination can reduce drilling and completion efficiency, increase formation damage risk, and drive-up project costs.

Filtration Products, Equipment, and Services

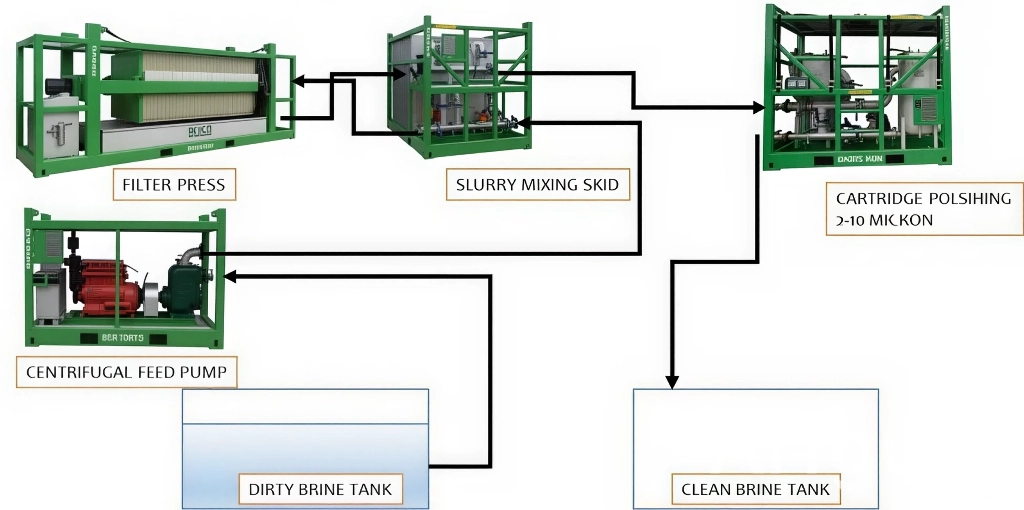

Our filtration process equipment package consists of a filter press, pre-coat slurry tank, powder handling unit, and cartridge filter unit to provide continuous filtering of solids-free completion fluid. The system has a small footprint designed for operational efficiency while offering a safe working environment.

Safety Angola has the complete filtration package, the Twin Vessel/Cartridge unit and the Filter Press/DE unit which are merely devices that allow us to position the media so a viable amount of fluid can flow through the media, the more filter area the higher the filtration flow rate can be achieved.

Key Benefits:

- Enhanced Operational Efficiency: Clean, stable fluids reduce downtime and improve well performance.

- Formation Protection: Minimized risk of damage to the reservoir and surrounding formations.

- Tailored Solutions: Filtration systems customized to match your fluid type, processing parameters, and environmental standards.

- Environmental Responsibility: Effective solids removal with minimal impact on the environment.

Filter press with plate shifter for safe, quick and easy cleaning a filter press

Types of Filtration Equipment

The Diatomaceous Earth (DE) Filter Press

This unit is the work horse in the offshore brine filtration world; it can handle relatively high levels of solids contamination. The DE filtration system can remove as much as 90% to 95% of particulate down to 2 microns in size. A typical 1200 sqft DE filter press has a maximum flow rate of 12 to 15 Barrels Per Minute (BPM).

Types of Filtration Equipment

Slurry Mixing Skid

A slurry skid is a modular unit designed for mixing and dosing a filter aid, such as diatomaceous earth (D.E.), in industrial filtration systems. It is primarily used with a filter press to enhance the filtration process by preparing the filter media and maintaining the filter cake’s porosity.

Filtration dual mixing slurry skid is a complete unit for pre-coating and body feed of the filter press. The unit is complete with 2 mixing tanks both 17 BBL/2.7 m³, air driven pre-coat and body feed pump. The frame is equipped with a working platform for safe and easy adding filter aid (DE media) into the mix tanks.

The unit can be optionally supplied with a manifold to unit two filter presses in parallel (also known as twin press set-up).

Types of Filtration Equipment

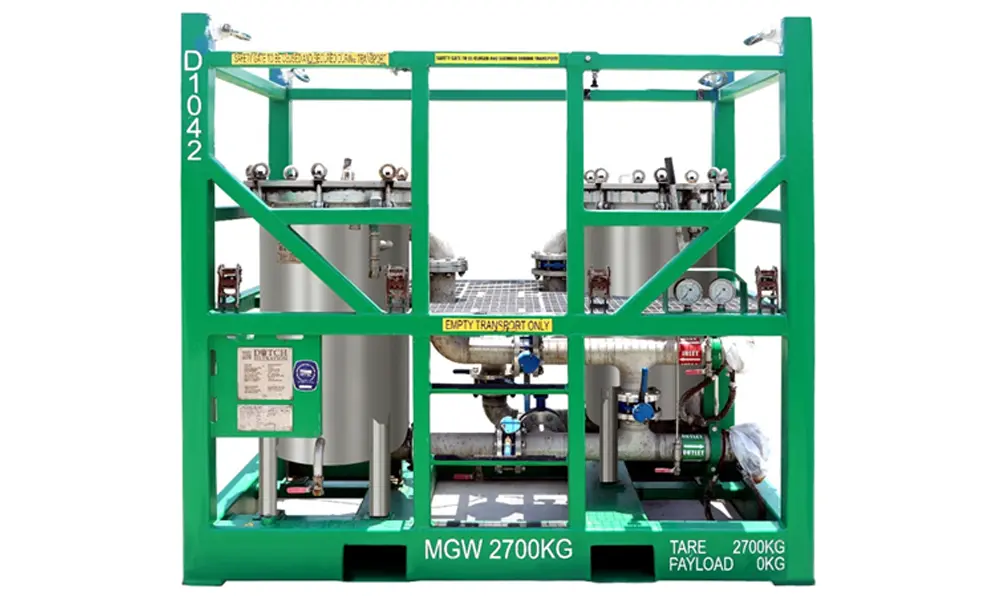

The Twin Vessel Cartridge Filter

IDEC Dual Vessel Cartridge Filter Unit is the most efficient filter unit. The unit is designed based on the key drivers of HSE, efficiency and reliability. The Rudi Quick Opening Closure allows the operator to fast and safe open and close the filter housing for change out of filter elements. Our unit is designed and built in accordance with DNV 2.7-1/ ISO10855/ EN12079 and certified by DNV.

IDEC DFC24 unit has two housings of each 50 cartridges and 6 valves for parallel, in series and by-pass operation.